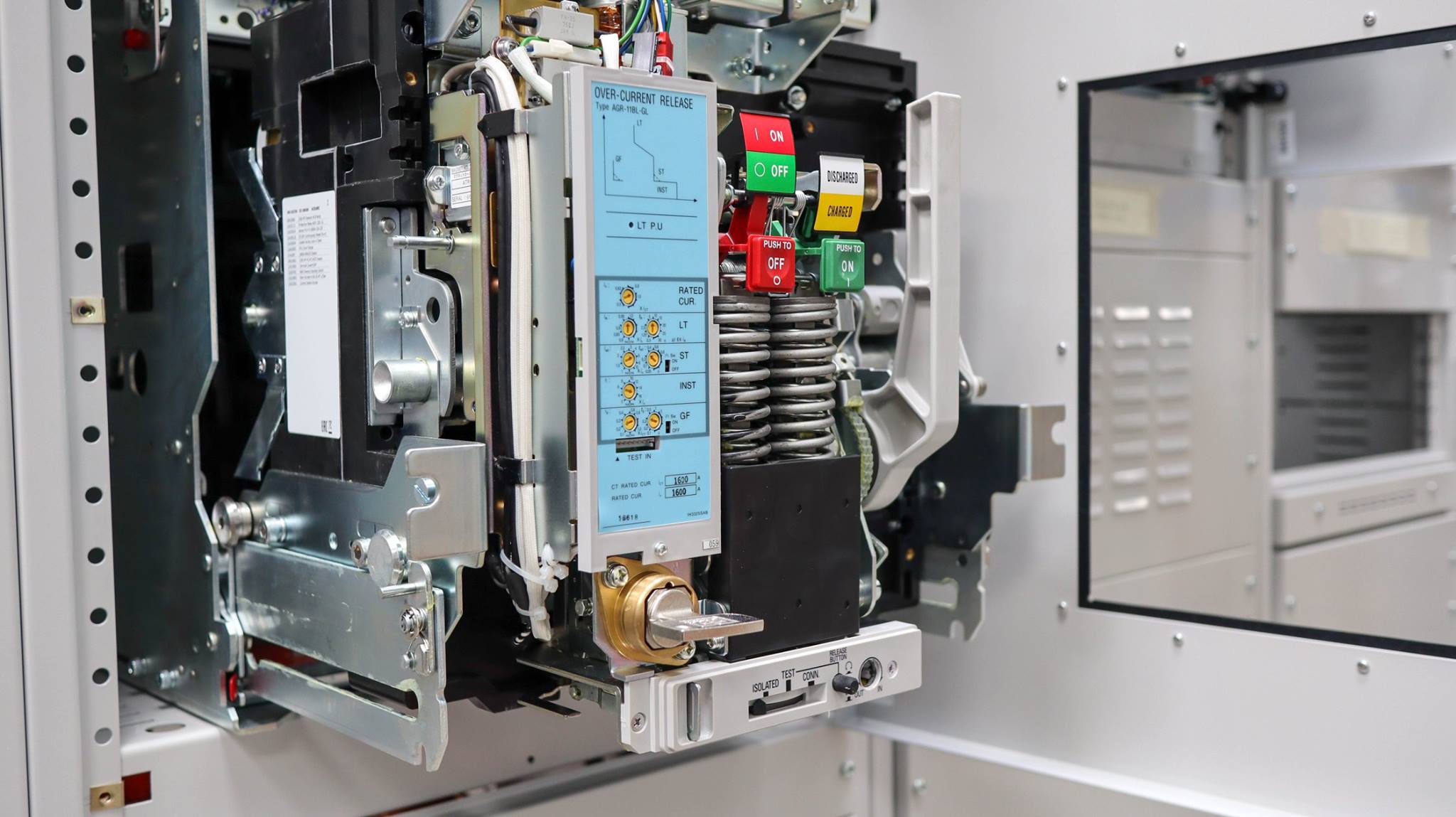

LVAC Distribution Switchgear

Power and distribution is fundamental to the continuity of your building infrastructure.

Need an LVAC switchboard?.

You have the power to look after your infrastructure.

Don’t leave your business exposed, replace your old switchgear to save down time.

Most people take switchgear for granted. The equipment that sits in the basement Or locked away down in the dungoens.

Without it, medium to large projects would not be possible.

Taking a main incoming supply and creating a reliable sub distribution system is key to your companies fabric.

Maybe your existing switchgear is past its due date.

We often visit companies that have switchgear up to 30 years old. Leaving something that long without re-investment is asking for trouble.

Check that your switchgear is suitable and compliant with todays standards.

Behind every great company is a great switchboard.

Your business relies on power and power consumption. We can offer you a reliable solution to enable your company to expand and grow with the times.

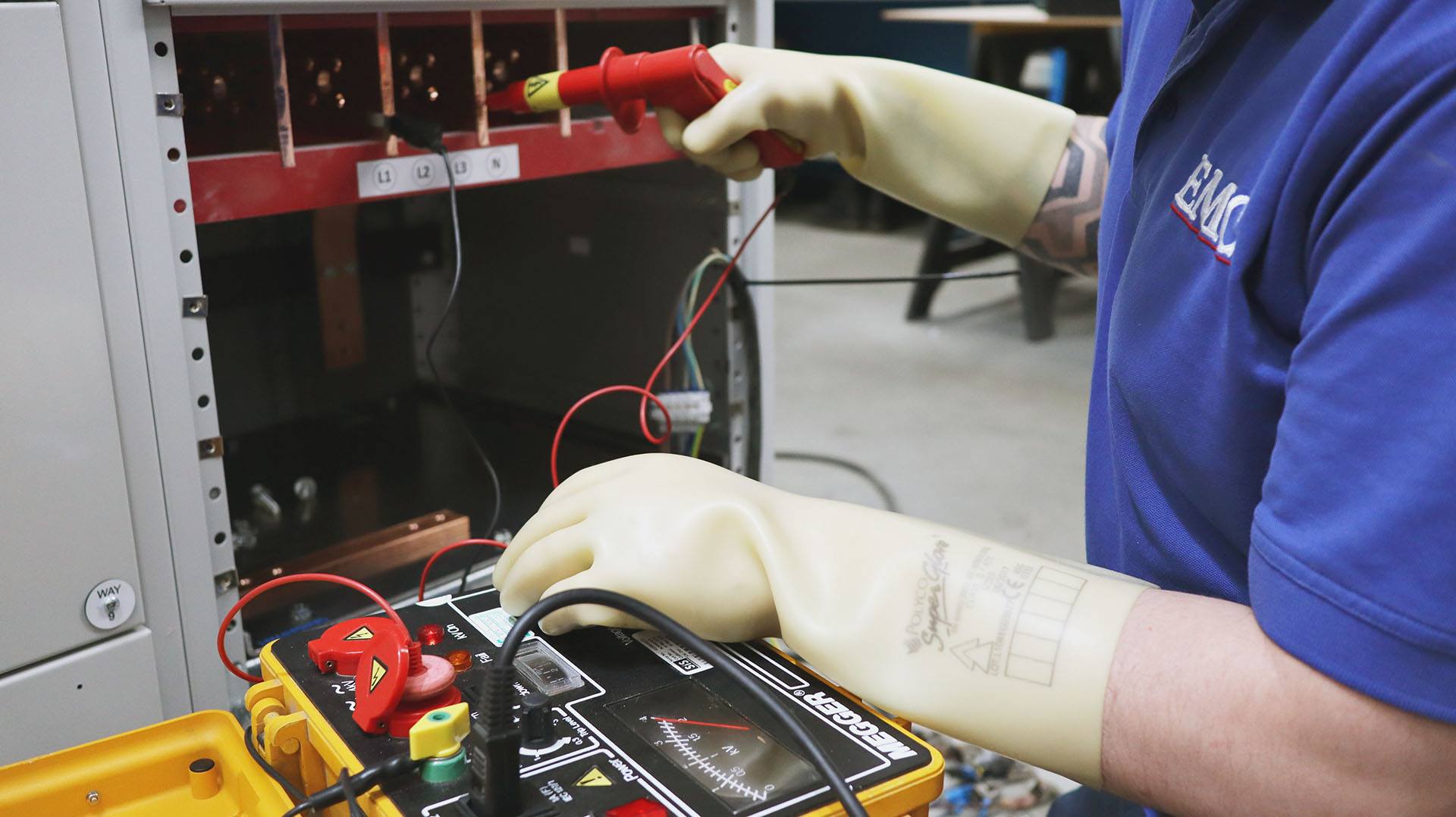

Tested and built the right way.

- Flash tested (If applicable).

- Schematics produced.

- Controls thoroughly tested.

- Double verification standard.

- From factors to industry standard.

- Wrapped and despatched via hiab.

- Method Statements

- Risk Assessments

- Trained Staff

CSCS

A Construction Skills Certification Scheme (CSCS) card is the leading skills certification scheme in the UK construction industry.

All EMC employees carry the CSCS card on their persons.

It serves as proof to employers that you are properly qualified and possess the necessary skills and knowledge to work in the construction field1.

Essentially, having a CSCS card demonstrates your competence and commitment to safety and standards within the industry.

FAQs

First Aid

Our employees have attended recurring first aid refresher courses.